Zippy Technology Corp.

Established in 1983, Zippy Technology Corp. was known for its micro switch technology. In the present day, Zippy has grown into a company with professional R&D teams and high-quality manufacturing processes. Zippy Technology Corp. is comprised of business units which specialize in micro switches, high-performance industrial power supplies. With its specialization to R&D and core competences, Zippy is well-recognized among international brands. Its products are widely used in consumer electronics, IT peripherals, communication products, household appliances, medical and industrial products, and automobiles.

Switch Division Profile

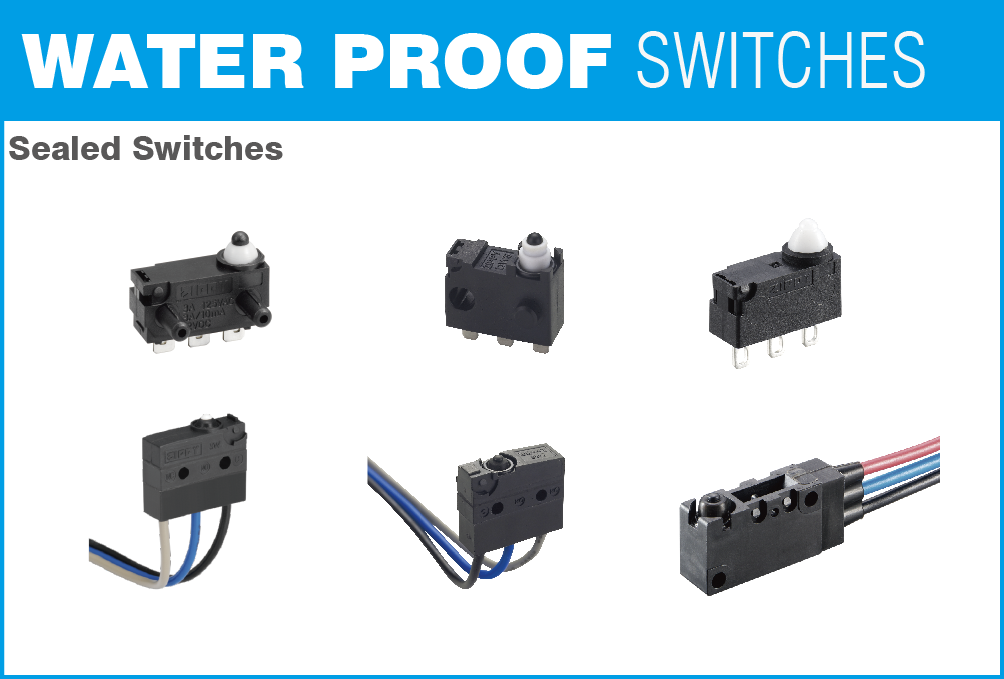

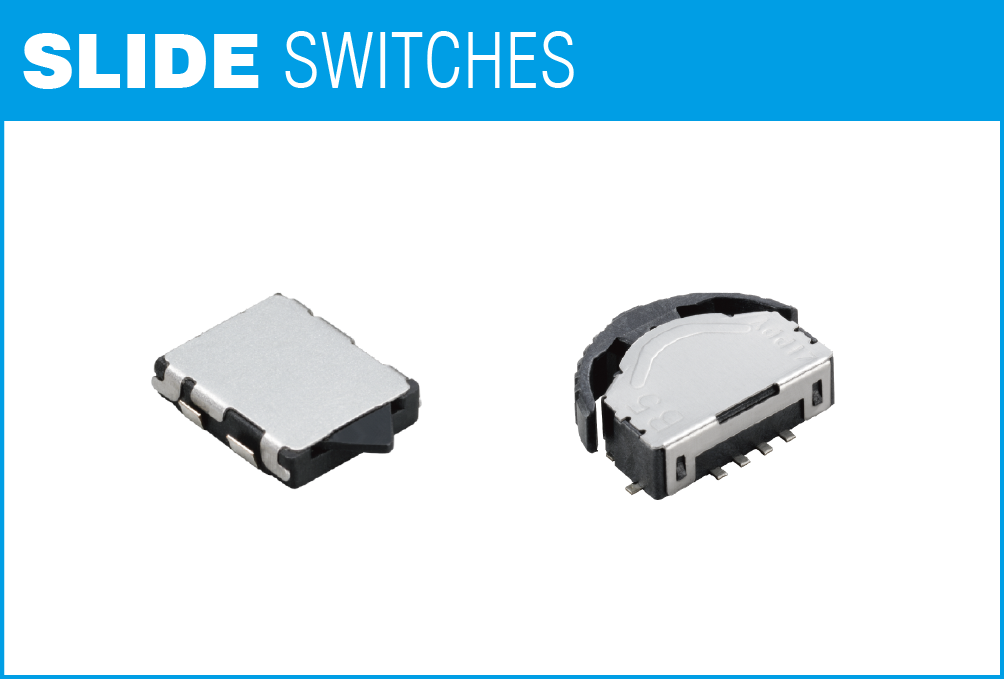

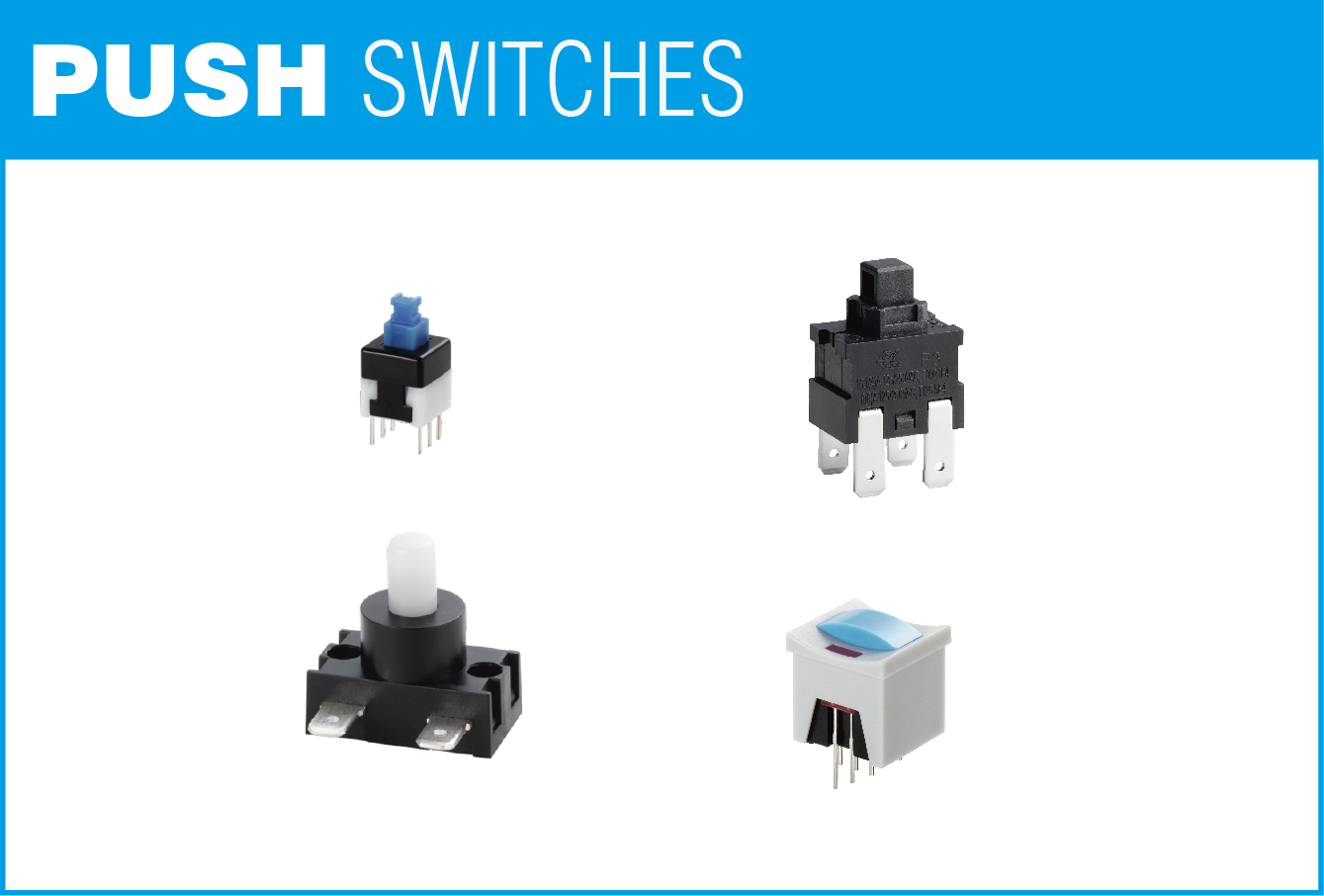

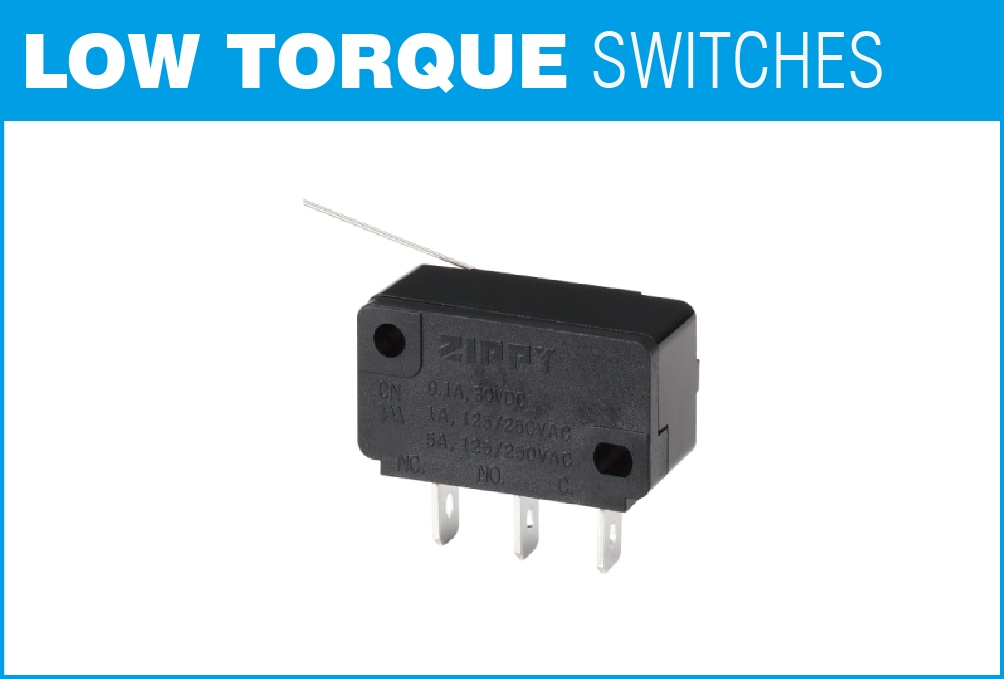

Founded in 1983, ZIPPY Technology Corporation started with the development and manufacture of micro switches. With the continuous effort over the years, ZIPPY has accumulated industrial best R&D capabilities and become one of the biggest and highest quality manufacturers. Currently the company has two major divisions which include Power and Electronic Components. The Electronic Components Division focuses on the development of micro switches. Our products are certified by many well-known companies worldwide and widely used in consumer electronics, computers, communication devices, home appliances, industrial equipments, automobiles, and medical devices. The development in technology and manufacturing are ZIPPY’s unique advantages among other industry competitors. The R&D team has developed numerous switches such as waterproof switches or customized components according to our customer’s demands. Currently ZIPPY owns more than 341 switch related patents worldwide. Quality is also one of our main focuses as well. Since 1994, ZIPPY has been certified under ISO9001, IATF-16949 and some other major international certifications. In recent years, ZIPPY also use automated production process in order to increase quality and competitiveness of our products. ZIPPY has incorporated the concept of Positive Thinking, absolute transparency, and cooperation into our corporate culture and daily lifestyle. Therefore we have a team of responsible and honorable staffs with great ideas to cooperate under this business model. ZIPPY’s biggest asset is our employees, we service our customers with this greatest asset to create a better future and perpetuate the business.

FACTORY

ZIPPY one of the leading switch manufacture in this territory, To keep ahead among the same lines of work, depending upon not only the better quality but core technology and advanced process also. We therefore aim at R&D on newer process continuously and Improvement in advanced production procedures unceasingly.

There are two factories under this Division, located in Taiwan and China separately.

.Taiwan Shu-Lin Factory: Guan Yan Street, Shu-Lin Dist, New Taipei City, Taiwan.

.Dong Guan Factory: No. 108, Jin Chai Road, Niu Yang Community,Liao Bu Town,Dong Guan City, China

ZIPPY possess the following: R&D capability in critical components; Complete production system; Reliable quality of product: Well-versed experience in production .

R & D GROUPS

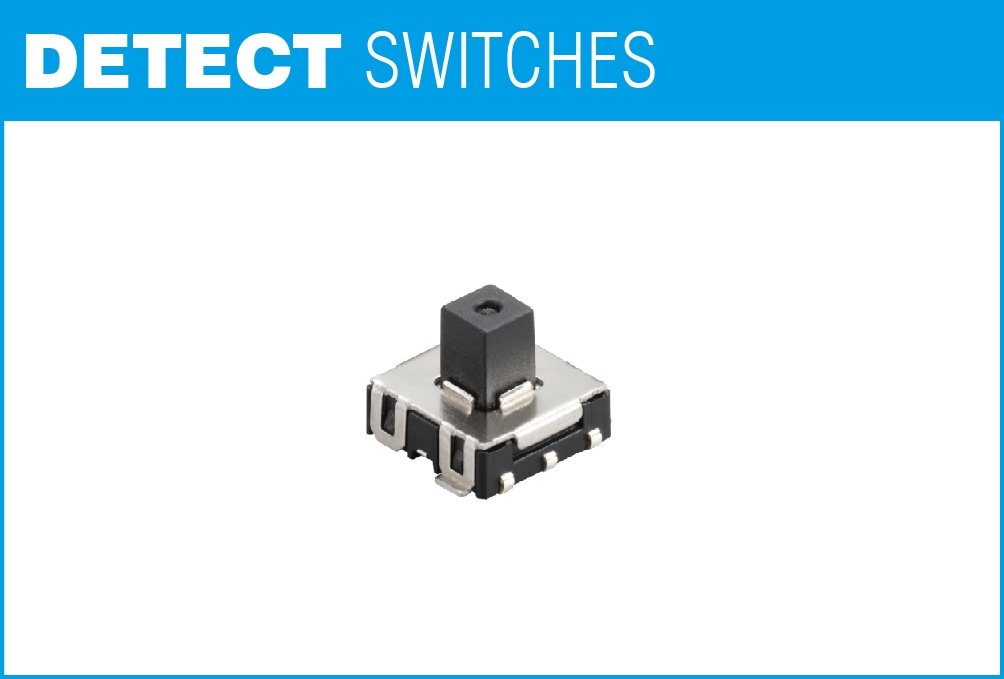

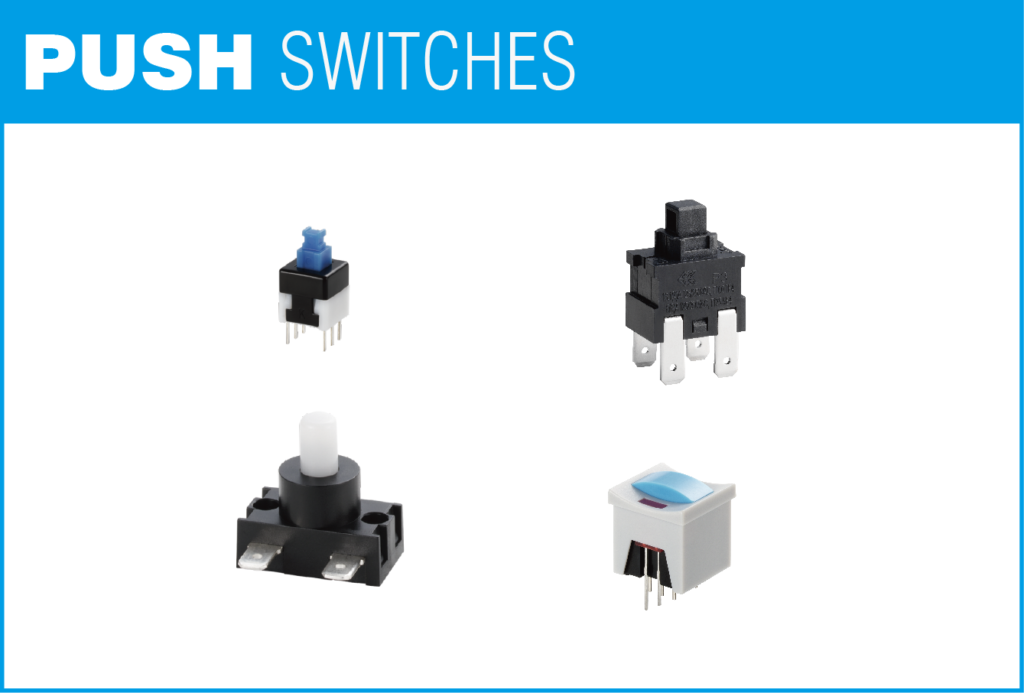

Zippy EC team dedicates in researching and developing high performance switches and owns more than 155 worldwide micro switch patents. Besides holding the essential technology of manufacturing IP67 waterproof switches to market and high rating and long life than other switch competitor’s. Zippy has broadened our service into OBM / ODM for many years, and we are extending our product lines to customize home appliances, special industry and automotive switch modules field in order to competitive of our products.

R&D equipment

Drafting Software:

Auto Cad, Pro-E,

Professional grade measurement equipment:

Projector, Optical, Microscope, elasticity tester, tension meter, micrometer, height meter, calibrators, and Torque meter.

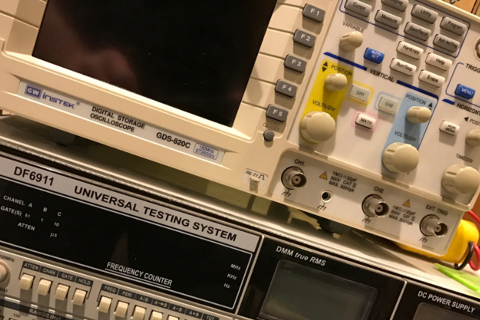

Verification equipment: such as:

UL approved Testing Simulators: including loading, various kind of resistors, inductors, motors, lamps, and power supplies. In addition to the self- developed Life of Equipment Testing System.

Environmental simulator equipment:

CTCH equipment, Cold – Hot attack equipment, Vibration tester, HI – temperature oven, Dust proof – Water proof testing system, Salt spray testing system, Tin Oven, Static testing equipment. Re-soldering oven etc.

Other tesung equipment:

MicroOhm meter, Safety Code verification equipment, Friction Tester, Temperature recorder, and Acid-Alkaline examiner etc.

Quality Control

ZIPPY’s first Division, the Components Business division, was established more than twenty (30) years ago, and becomes a leading switch manufacture in this territory. ZIPPY win customers’ trust and praise warmly only because of her product of the reliable Quality, Any piece of product before delivery are under strictly test and control by QA Center.

Advanced testing equipment and professional QC engineer group

“Good work to be produced from advantageous instruments” a folks adage. To the quality control, various kinds of precise and applicable instrument are necessarily required for testing and inspection.

The imported equipments in QC Center are consisting of: overhead projector, micro ohmmeter, Calibrator, Gauges, tension force measurement etc. To meet the special tooling requirements, the internal R&D department is responsible for the fabrication and maintenance of such work.

QC engineers’ work experience and qualification of ten years in average, are all penetrative, well versed and professional to the inspection, being one of ZIPPY’s most valuable property.

Perfect QA System

ZIPPY’s Components Business Division, an awarder of ISO9001 Certificate, and for the production line of automobile switches, we also have been certificated by IATF-16949 standard. To get along with the new trend of the world, upgrading demand in qualification to a higher level, marching toward some other industries in higher requisition. QA Center’s theory of operation are; seek trust from facts, be practical and realistic, customer the first, perfect Quality Control, improved quality of product, and eternal operations. As for revision and renewal of all relevant documents such as: Inspection Guide, PMP, QC Engineering diagrams, SPC, FMEA, and inspection report, etc. are part of Center’s work as well.

To have a real time response, periodical discussion, control in solution and correction of quality problems are held regularly/Irregularly. In the respect of new product development, to minimize any possible error in mass production phase, QA Center participate in the development phase firstly, such as: inspection, method, study in the applicable testing equipment and it’s feasibility, given comments in professional point of view, provision of useful reference data and/or suggestion based on the results of inspection in trial production phase. Customer Service Office provides a soonest response in either clarification and explanation, user’s guide or some assistance improving way of operation. In conclusion, customer’s smoothly reception and/or delivery shall be our most favorable aspiration.

Projekt

Przygotowanie projektu zaczynamy od opracowania modelu jak najbardziej zbliżonego do oryginału przedstawionego przez klienta dostosowanego do wymagań procesu technologicznego. Opracowane są: sposów montażu i zabezpieczenie przed wpływem czynników zewnętrznych.

Wskazane jest dostarczenie przez klienta wzorca wydruku (CROMALIN)

Całość projektowania przebiega przy użyciu specjalistycznego oprogramowania CAD i drukarki 3D.

Produkcja

Przygotowane w procesie projektowania pliki przekazywane są do produkcji gdzie wykorzystywane maszyny CNC, LASER, WATERJET przygotowują elementy składowe produktu. Sprawdzanie poprawności wydruku ( CROMALIN)

Montaż i testowanie

W procesie montażu koncowego przygotowane komponenty składa się w całość a następnie testuje . Gotowy produkt po testach wygrzewany jest przez 24h.